Suzuki FA50 Moped Teardown

ID: 1264

Description: My 1984 Suzuki FA50 was exhibiting some...

Steps:

- There's no rage against this machine.

- Looks great, except it doesn't run.

- Its 50 cc engine lets me go downhill at almost 28 MPH when it does run. Uphills, not so much. Depending on the hill (and my head start), I may or may not have to walk it up.

- The seat advertises "185 LB max." In the USA??

- The above weight limit can be used in a "Yo mamma" joke. Note that I said can be, and not should be.

- Safety first. Disconnect the battery and store it in a safe place.

- The battery's readily accessible underneath the seat.

- In retrospect I figured out i that I didn't need to remove the exhaust cover, but what the heck... When in Rome, right?

- Took off the air intake box.

- That's contractor-grade 3M packing tape holding the airbox together. Only the best for my moped.

- I went to the other side of the bike and removed the carb/oil pump protective cover.

- The foot rest came off next, in order to gain access to the engine and spark plug.

- While down there, I unplugged the spark plug cover.

- I then proceeded to access the wiring underneath the gas tank.

- The wires needed to be disconnected in order to remove the frame away from the engine/crankshaft.

- First I removed the protective brace on top of the oil/gas tanks using a 10 mm socket wrench.

- I had to take off both oil and gas caps in order to remove the plastic protective cover.

- I set aside the fuel tank and bam! -- the wires were ready to be disconnected.

- The wires must have been minding their own business since '84... Separating them was quite a challenge. Thankfully they had those round connectors on them, so I didn't have to solder or crimp anything when reassembling the moped.

- I then unplugged the emergency fuel valve .

- The valve should remain in the "On" position while working on the moped.

- I paused for a minute to enjoy a cold cup of Diet Coke, and to drain all the 2-cycle oil...

- I got the Goliath "freezer" mug in Six Flags Magic Mountain about 6-7 years ago. Best investment I ever made, aside from marrying the wife. It's the gift that keeps on giving!

- Ikea bowls come in quite handy. Turns out there was enough 2-cycle oil to fill the entire bowl to the brim!

- I had a difficult time figuring out what I was doing in these pictures. According to the manual, I was removing the oil pump cover and oil hose.

- Unscrewing the smaller valve, which I believe to be the carburetor choke cable.

- My culprit resides beneath the carburetor top cover. Even though I reassembled the moped, I'll have to investigate the throttle cable going into the carburetor.

- Rear brake gets disconnected next. The cable needs to be free since the brake lever will come off with the rest of the frame.

- The rear spring gets unsprung using a 14 mm socket wrench.

- Disconnecting the spring may be potentially dangerous, as it may be under tension.

- Nothing crazy happened when I disconnected it, however.

- Finally, the large frame screw can be removed. This is the last piece of hardware holding the frame to the rear wheel / engine.

- I had to use two 17 mm wrenches -- a socket on one side, and a ratcheting wrench on the other.

- And just like that, the frame comes off!

- A 12 mm and 10 mm hex socket take care of the muffler.

- Now on to the engine.

- Spark plug comes out with a strong flick of the wrist.

- The plug looked like it was the original one that came with the moped. Dirty dirty!

- I continued by removing the front part of the engine using a 10 mm socket wrench. I found plenty of buildup inside.

- I wanted to see what a "flywheel magneto" looked like, so I decided to remove this cover. I figured anything named after an X-Man is worth a look...

- I stripped the Phillips originals while taking the cover off. I replaced them with appropriately-sized 20 mm hex-head screws.

- This is a 65 mm replacement I ordered online, along with news seals and stuff.

- Some shots of the engine...

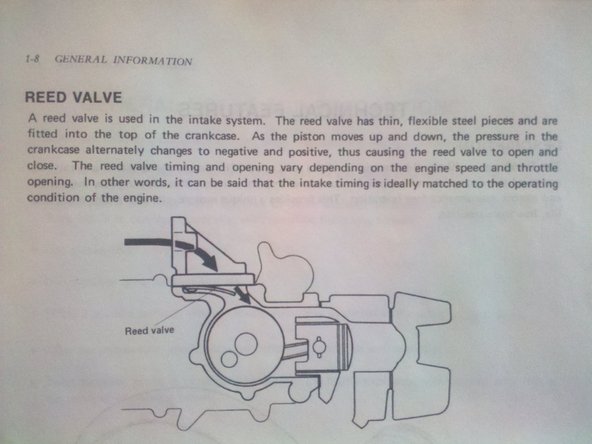

- The reed valve comes right off. You can see the engine internals from the hole -- cool!

- I was careful not to accidentaly put any crap inside the engine. I figured the Shuttle wouldn't run well on dirt and Cheerios.

- The reed valve is a very important part of the moped, according to the service manual. The metal bars have to be bent a certain way, and other stuff.

- I had quite a difficult time shooting a "final layout" shot. I gave up after 5-10 pictures; this one was the best of the bunch.

- That's it! Hope you enjoyed my teardown!